Before starting to use color-coding in your food production setup, it is essential to address the following questions:

You must identify all potential food safety hazard risks (allergens, microorganisms, foreign bodies), in your production setup, based on the type of food you produce as well as your production processes, customer segment, legislation, and certification(s). If you have a HACCP plan, you will have identified these hazards and assessed the associated risk already.

If the answer is yes, the ideal color-coding solution is to allocate a specific color to the tools and equipment that come into contact with these allergens.

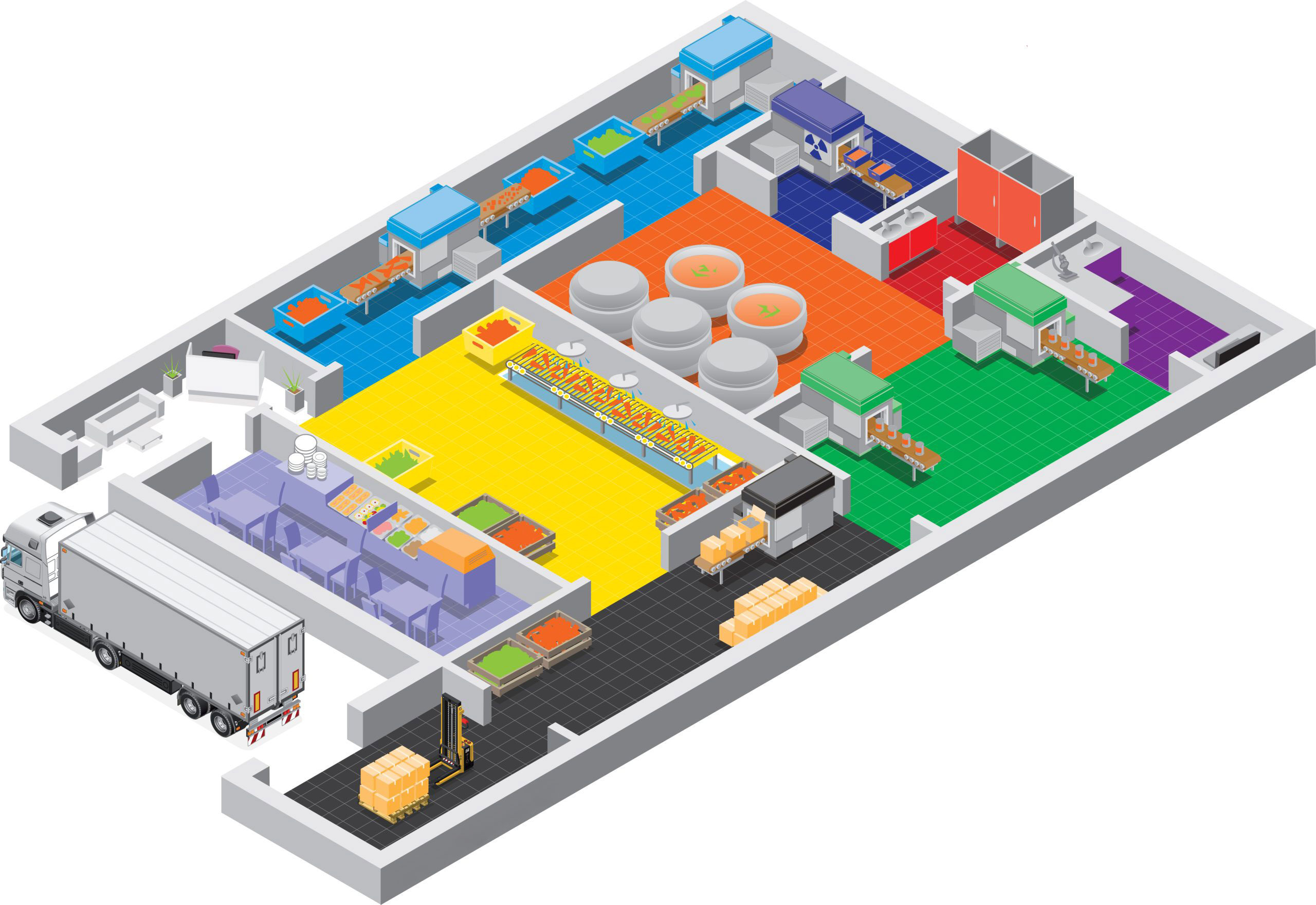

If your production facility is already divided into zones, you can base your color-coding on your existing zones, if it makes practical sense.

Give each zone its own color to make it easy to identify the equipment and tools that belong to each zone.

Zone division can also be applied at the production line level to limit the risk of cross-contamination between one line and another. This type of zone control involves allocating a designated color to equipment intended for use exclusively within a particular area and/or on a particular production line.

Vikan is a leading supplier of hygienic cleaning tools and insight for the food & beverage industry and other hygiene-sensitive environments in North America.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

With existing and emerging threats, food safety has never been more important to food manufacturers in protecting their consumers and their organization.

Color Coding

Laboratory, Color Coding, Food Safety