In the competitive food manufacturing landscape, minimizing waste is no longer just an ethical choice – it's a crucial driver of profitability and sustainability. Understanding and tackling waste at every stage of your operation can lead to significant cost savings and a stronger bottom line. Efficient inventory management plays a vital role in this effort.

Various forms of waste can impact food processing, including by-products, spoilage, overproduction, and even "ugly produce". These issues are often fueled by production inefficiencies, packaging problems, improper storage, and supply chain disruptions.

So, how can food manufacturers effectively reduce waste? Several key strategies can be implemented, and many are directly linked to optimized inventory management practices:

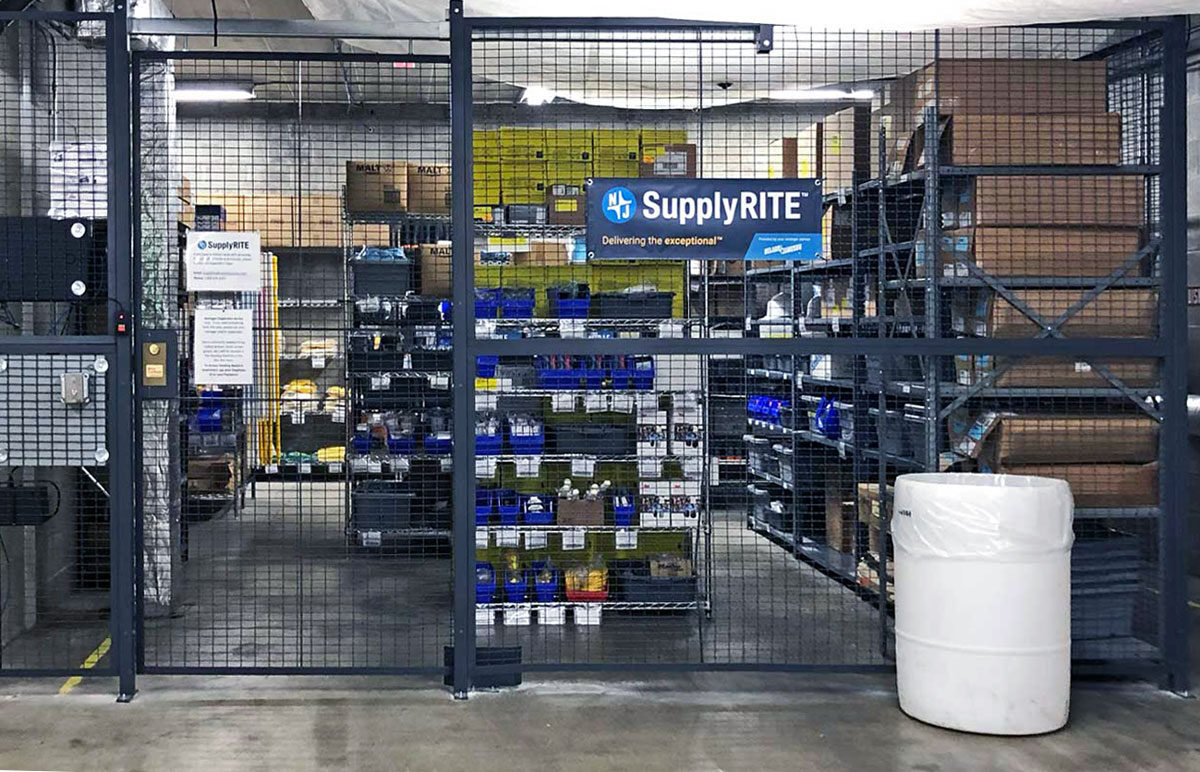

Reducing waste in food processing has substantial benefits. Environmentally, it lowers greenhouse gas emissions and minimizes landfill use. Economically, it can reduce disposal costs, lower raw material expenses, and improve operational efficiency. As an inventory solutions expert for Nelson-Jameson, we understand that effective inventory management is a cornerstone of any successful waste reduction strategy. SupplyRITE is designed to provide the control, visibility, and automation needed to minimize waste and streamline your food processing operations.

Ready to manage your inventory and reduce waste? Contact Nelson-Jameson today to explore how SupplyRITE can be the inventory management solution you need.

Adam is a 10-year veteran of the food manufacturing industry and builds strong customer relationships through customized CMI/VMI solutions, optimizing customer inventory and streamlining operations.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Inventory Management