With the signing of the Food Safety and Modernization Act (FSMA) in 2011, many food processors are taking proactive steps by instituting color-coding as part of their Good Manufacturing Practices. These practices follow guidelines of Hazard Analysis and Critical Control Points (HACCP) — a management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material product, procurement and handling, to manufacturing, distribution and consumption of the finished product. Currently, HACCP procedures have been developed for dairy, juice, seafood, and retail and food service.

But in examining the intent of the HACCP procedures, one can easily see how other types of processing facilities could also benefit from color-coding systems. Processors who work with chemicals, pharmaceuticals, trash, recycled materials, sanitation, and other raw materials or are concerned with manufacturing hygiene could also consider how color-coding might benefit their facilities.

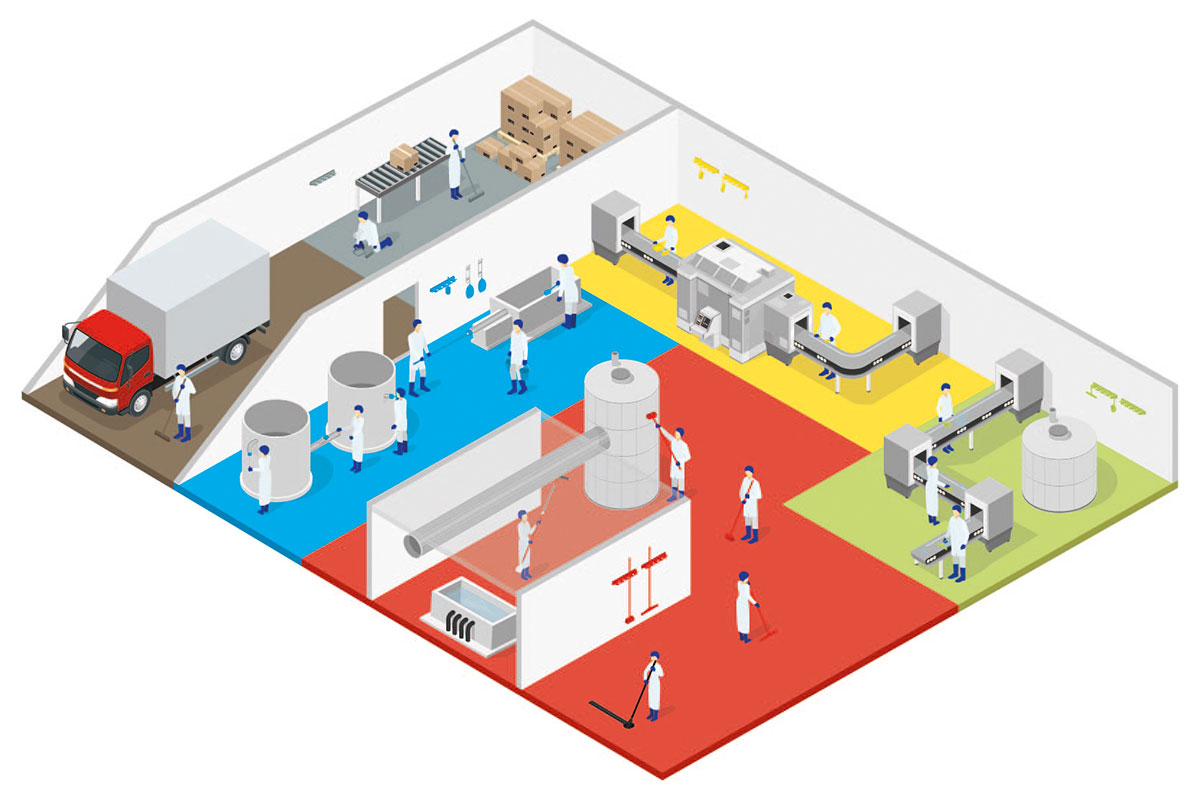

First, color-coding can be implemented to provide “zone control” within a food processing or food service facility. (Learn more about color coding in our complete guide) Different colors can be assigned to each step in the process or by manufacturing lines, whatever makes sense. When colors are assigned to zones, confirming that a tool is misplaced is easy, and tracing it back to its point of origination is quick. This level of traceability can translate to the prevention of costly recalls.

Second, color-coding may be useful in instances where zones aren’t necessarily required, such as dividing workspaces. For example, “Red” could mean “1st Shift” while “Blue” could indicate “2nd Shift.” In this situation, shift employees are taught to understand which colored tools are for their shift, so they’re less likely to use another shift’s tools. Using color-coding to designate workspaces in this way can be particularly helpful to companies that closely monitor tool and equipment costs. The result can be a reduced incidence or misuse of tools in unapproved areas, as well as fewer lost or misplaced items.

Third, color-coding is often part of businesses that follow a 5S System, which integrates color “cues” throughout a work process or facility to reduce waste and optimize productivity. Color-coded tools intuitively complement and support the goals of a 5S workplace. The color-coding promotes a workplace culture where tools and supplies are placed where they are needed and well-maintained for the longevity of use.

Finally, color-coding can also be employed to distinguish cleaning versus sanitation in a processor’s maintenance routines. For instance, “Black” is a

common color used to identify cleaning tools used on floors and around drains. Other colors can be selected to designate tools that are appropriate for sanitizing food contact surfaces or to differentiate between tools that are specified for use with particular chemical agents. This practice can also help prevent the undesired occurrence of using a powerful cleaner on the wrong equipment.

Many factors can influence a processor’s decision to implement a color-coding system. Changes in industry regulations or a new manufacturing line can often be a first prompt.

To decide if color-coding is right for your facility, consider these criteria:

If you answered YES to any of the questions above, your processing facility is a strong candidate for color-coding.

Color-coding can be particularly helpful for maintaining strict work zones, reducing the risk of pathogens, allergens, and other foreign contaminants affecting their operations, or minimizing miscommunication throughout a facility’s processes.

Once a facility has determined that color-coding is a positive decision, care should be taken to implement a color-coding system that makes sense. Here are some tips for assuring a well-implemented color-coding system:

After you’ve identified the hazards and the Critical Control Points that can benefit from color-coding, make sure you make your color assignments as simple and logical as possible. A good rule of thumb is to assign only one color to each zone. Make sure the colors you select make sense in relation to your process. It’s also a good idea to check the availability of colors in the tools you need before finalizing your plan. This will allow your operation the greatest flexibility.

Once you’ve made logical color assignments, consider where the color should be applied to ensure the process is followed properly. Consider your material

handling, tubs, machinery, labels, plant signage, storage closets, employee clothing, and floor markings. Key items within a particular zone or Critical Control Point should be identified with the appropriate color to ensure consistency. Be sure your documentation at each point of use is also consistent with the paperwork used by your Quality Manager and Purchasing Department so you can more easily determine when color-coded work items have been misplaced, lost, or stolen, and items can be re-ordered with greater ease.

Once you decide to implement a color-coding program, be sure you also have a communication strategy for how the program will roll out to your employees. Most processing facilities already have guidelines for how to communicate changes in processing procedures. It’s often recommended to meet with shift employees first and then communicate the program to all employees. It’s considered a best practice to include details about your color-coding program in your operation’s Preventive Control or Prerequisite Procedures, such as GMPs, SOPs, CCP, or Non-CCP. Following this best practice will go a long way in helping to ensure company-wide adoption, consistency, and compliance with any color-coding scheme you may choose to implement. Whatever you do, be sure to implement the program in its entirety. It’s best NOT to have part of your facility following the old protocol while another part of the facility is using your new color-coded protocol.

Color-coding is an effective way to minimize cross-contamination or other hazards within a processing facility. While not a requirement of many regulating

bodies, color-coding can demonstrate a company’s dedication to the quality and consistency of their products while maintaining a high level of safety for both their employees and end users.

Information provided by Vikan®

Vikan is a leading supplier of hygienic cleaning tools and insight for the food & beverage industry and other hygiene-sensitive environments in North America.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

With existing and emerging threats, food safety has never been more important to food manufacturers in protecting their consumers and their organization.

Color Coding

Laboratory, Color Coding, Food Safety