As Director of Safety and Corporate Compliance at Nelson-Jameson, one of my primary areas of focus is helping our partners and customers navigate the often ambiguous complexities of food safety and regulatory compliance. Our motto: Proactive measures are the most effective way to ensure a safe and successful operation. While just a singular piece of the puzzle, color-coding a facility can play a powerful part in keeping consumers safe.

Facing stringent government regulations, and maintaining compliance is an important undertaking for any food manufacturer. And while it’s not exactly a mandatory requirement, color coding is a practice that's highly favored by regulatory bodies such as the FDA and USDA, particularly under the Food Safety Modernization Act (FSMA). It’s easy to see why. Color coding provides a simple visual (and easily documented) method for preventing cross-contamination, which is a key aspect of any proactive food safety plan.

By incorporating color-coding into a broader Hazard Analysis Critical Control Point (HACCP) plan, food manufacturers create clear standard operating procedures that go a long way in improving preventive measures. We see these improvements everyday in the plants of our partners and customers who rely on Nelson-Jameson's color-coded solutions as well as our expertise, and complementary training and asessments.

At Nelson-Jameson, we also see the evolving threats to food safety — both new and old — and make it our mission to empower food processors to have the tools necessary to keep our food supply safe.

Below we share more about why color-coding is so important for any food manufacturing facility’s regulatory compliance efforts. And learn more about color coding with our complete guide!

As we mentioned above, Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practices (GMPs) are crucial in order to promote food safety inside and outside of a plant. These systems emphasize preventative measures to identify and control potential hazards. Color coding directly supports HACCP and GMP implementation by:

Color-coded tools and equipment (and designated color-coded areas for each) help prevent cross-contamination, which is a major food safety concern that's addressed by both HACCP and GMPs. By separating different food types or processing stages with distinct colors, processors can minimize the risk of allergens, pathogens, or other contaminants coming into contact with products. Learn more about why color coding is a powerful tool when separating allergens in this recent Nelson-Jameson blog post.

In addition to tools and equipment, color-coded labeling and tagging systems can also be integrated into any program. This will allow for quick identification of products and even their origins. Aside from simply knowing the tools, this can also be crucial for recall management which is another key component of regulatory compliance. If a problem arises, color-coding facilitates efficient tracing of affected products, minimizing the scope and impact of a recall and saving time and resources.

Color coding can also designate cleaning tools and supplies for specific areas or purposes, ensuring that equipment used for raw materials isn't used for finished products. This supports GMPs that might be specific to sanitation and hygiene.

"Proactive measures are the most effective way to ensure a safe and successful operation. While just a single piece, color-coding a facility can play a powerful part in keeping consumers safe."

Compliance with regulations set by agencies like the FDA and other authorities is not optional. But how does color coding specifically help meet their given standards? Here are some examples:

A well-defined and clearly communicated color-coding system makes it much easier for regulatory inspectors to assess the facility's adherence to their various safety and hygiene standards. The visual clarity of the system demonstrates a commitment to compliance and can facilitate a smoother inspection process for both the manufacturer and the inspector.

Being proactive is always better than being reactive. A documented and implemented color-coding system serves as evidence of a food processor's forward-thinking approach to food safety. It's a visual demonstration of due diligence in the event of an incident or regulatory inquiry.

Regulations are often complex, but color coding is actually very simple. By visually reinforcing safety procedures and best practices, color coding makes it easier for employees to understand and adhere to regulatory requirements. This reduces the risk of human error, which is a common yet preventable factor in food safety incidents.

Color coding also promotes transparency and accountability throughout the food processing operation. The system makes it easy for everyone, from employees to management to inspectors (to Directors of Safety and Corporate Compliance!), to understand the flow of the process and identify potential issues. This shared understanding creates a culture of compliance and continuous improvement as each individual grows with the program.

Nelson-Jameson helps complete any food manufacturer's color-coded system to improve food safety.

There is so much that goes into regulatory compliance, and color coding is an important piece. Don't know how to get started? Here are some easy steps:

Develop a Real Plan then Review and Audit the Plan: Create a detailed plan that outlines color assignments, their meanings, and how the system will be implemented, maintained, and reviewed and/or updated as needed. For example, the addition of new products, changes in processes, changes in internal and external regulations, or audit findings should automatically trigger a review of processes between scheduled reviews.

From a regulatory compliance standpoint, color coding should just be a tool among many on an organization's toolbelt. But it's a powerful instrument for achieving and demonstrating regulatory compliance to employees, inspectors, and maybe even customers who might be touring a facility.

By supporting HACCP and GMP implementation, adhering to regulatory standards, and promoting a culture of safety, color coding is essential for any food processor committed to protecting consumers and maintaining the highest levels of quality and safety. Investing in a well-designed, properly implemented, and regularly maintained color-coding system is an investment in both regulatory compliance and long-term success.

Have thoughts on color-coding systems? Reach out to Nelson-Jameson on social media and join the conversation!

Wendy is Director of Safety and Corporate Compliance, overseeing the implementation of SQF programs and supporting internal teams and distribution centers.

February 11, 2026

There is a critical link between worker safety and food safety, and nowhere is this more apparent than w...

February 3, 2026

Ensuring the safety and quality of dairy products requires a robust framework combining rigorous testing...

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

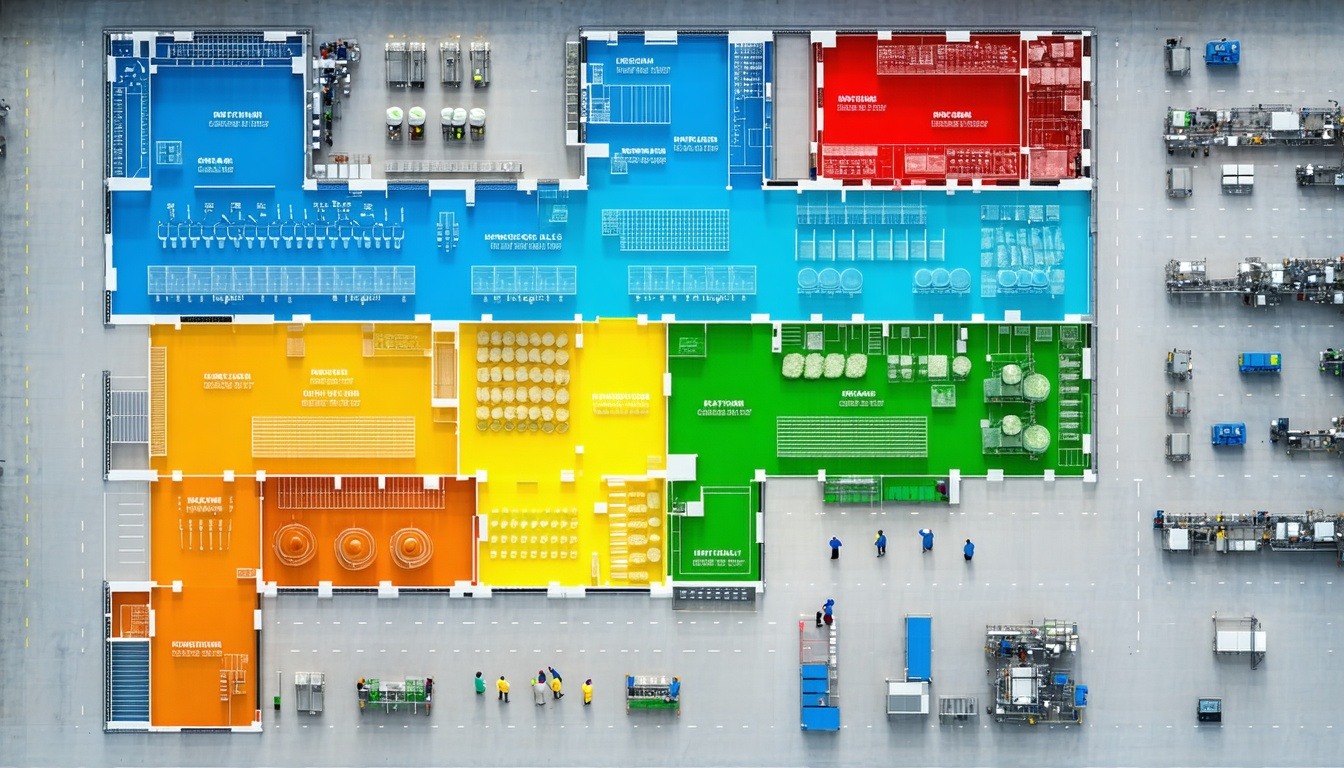

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

With existing and emerging threats, food safety has never been more important to food manufacturers in protecting their consumers and their organization.

Color Coding

Laboratory, Color Coding, Food Safety