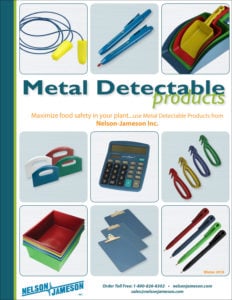

Using Metal Detectable Products in your facility is a great way to ensure the product that you ship out does not contain foreign materials. Metal Detectable Products are products that can be detected by a metal detector. In plastic products, such as pens, a metallic pigment is added to the resin during the manufacturing process, and it is this pigment that is actually detected by the metal detector. Other products, earplugs for example, contain a stainless steel ball bearing, which is then detected by the metal detector.

Having your Metal Detector calibrated to the correct settings is key to being able to detect foreign contaminants. The settings that you will need to use are based on many factors including the speed of the line, moisture content, and the material of the contaminant. Using calibration tools will help to determine what size of foreign material will be detected by your metal detector.

Having your Metal Detector calibrated to the correct settings is key to being able to detect foreign contaminants. The settings that you will need to use are based on many factors including the speed of the line, moisture content, and the material of the contaminant. Using calibration tools will help to determine what size of foreign material will be detected by your metal detector.

Nelson-Jameson offers a wide range of Metal Detectable Products, from pens and markers to scrapers and mallets. We also have several Metal Detectable Products that are also color-coded to help prevent cross-contamination in your facility. View our entire line of Metal Detectable Products or request a copy of our new flyer.

January 12, 2026

Gloves can force a choice between comfort and protection. But compliance, efficiency in usage, and worke...

January 2, 2026

From regulatory updates to evolving needs for operational efficiency, food processors spent 2025 adaptin...

December 10, 2025

What is OSHA's Regional Emphasis Program (REP) for the food manufacturing industry? The OSHA Regional Em...

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

Through a discovery call, virtual, or on-site assessment, Vikan SQF Practitioner certified specialists will assist in confirming that your system and cleaning tool inventory aligns with your risk management objectives while pinpointing any missing tools and enhancing maintenance and usage practices. Evaluate whether your existing tools are utilized in the most effective manner, or determine if a more suitable tool exists for the task at hand. Ensure that your tools comply with all relevant standards and regulatory requirements. Site evaluations encompass a summary survey, an overview of the location, a color-coded factory layout plan, product suggestions, a recommended order form, and a proposal for a follow-up survey.

Food Safety, Sanitation, Cleaning Tools, Color Coding

This is a comprehensive program for the food processing industry. Nelson-Jameson brings together the most extensive collection of color-coded products for material handling, product handling, janitorial, safety, apparel, QA/QC, and metal-detectable applications. With the right pieces, a color-coding system is a powerful tool in preventing cross-contamination of allergens and food-borne illnesses that can lead to sickness or expensive product recalls.

Food Safety, Sanitation, Cleaning Tools, Color Coding

Food Safety

Get Petrifilm Certified through our complimentary immersive workshop for managers, personnel, and teams. The workshop offers practical knowledge through hands-on training and networking with industry professionals and experts. Attendees gain an in-depth understanding of Petrifilm technology and valuable insights into effective environmental monitoring practices. Participants leave with a certification and a wealth of resources that can significantly contribute to elevating their plant's quality control standards.

Food Safety, Sanitation, Laboratory