Tank cleaning technology has advanced as improvements to hygienic standards have changed. As that change has taken place, priority has been placed on cleanliness of equipment and storage tanks, which helps to ensure quality in

food products.

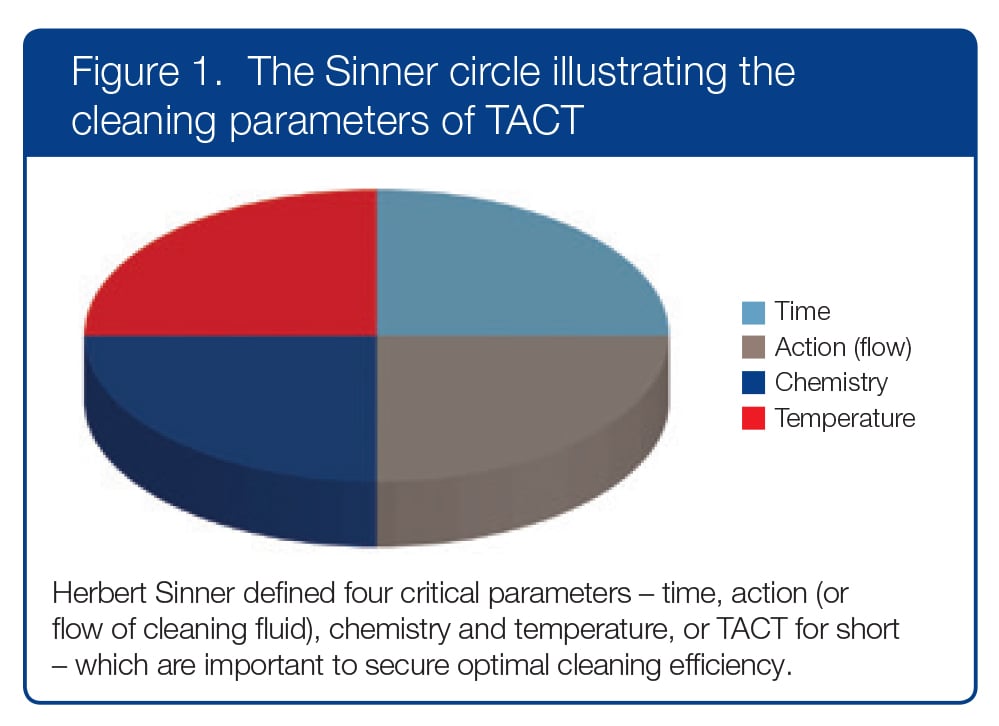

Many organizations such as 3-A have developed standards across the food industry specific to cleaning of a tank. Coupled with hygiene is the added task of reducing chemical and water usage. A common acronym that is used with tank cleaning methodologies is TACT which stands for Time, Action, Chemistry, and Temperature (see figure 1). New technology harnesses the time and action portions of the acronym and are displayed in the chart commonly referred to as the sinner circle.

Many organizations such as 3-A have developed standards across the food industry specific to cleaning of a tank. Coupled with hygiene is the added task of reducing chemical and water usage. A common acronym that is used with tank cleaning methodologies is TACT which stands for Time, Action, Chemistry, and Temperature (see figure 1). New technology harnesses the time and action portions of the acronym and are displayed in the chart commonly referred to as the sinner circle.

For your reference, we have several videos on our YouTube channel that can explain this technology further.