Color-Coded Resource Hub

The Ultimate Guide to Color-Coding in Food Manufacturing

Color-coding in food production minimizes contamination risks, enhances safety, & extends tool life, leading to cost savings & improved work environments.

Featured Posts

March 25, 2025

Color Coding for Food Safety: A Crucial Part of Regulatory Compliance

As Director of Safety and Corporate Compliance at Nelson-Jameson, one of my primary areas of focus is helping our partners and customers navigate the often ambiguous complexities of food safety and regulatory compliance. Our motto: Proactive measures are the most effective way to ensure a safe and successful operation. While just a singular piece of the puzzle, color-coding a facility can play a powerful part in keeping consumers safe. Facing stringent government regulations, and maintaining compliance is an important undertaking for any food manufacturer. And while it’s not exactly a mandatory requirement, color coding is a practice that's highly favored by regulatory bodies such as the FDA and USDA, particularly under the Food Safety Modernization Act (FSMA). It’s easy to see why. Color coding provides a simple visual (and easily documented) method for preventing cross-contamination, which is a key aspect of any proactive food safety plan. By incorporating color-coding into a broader Hazard Analysis Critical Control Point (HACCP) plan, food manufacturers create clear standard operating procedures that go a long way in improving preventive measures. We see these improvements everyday in the plants of our partners and customers who rely on Nelson-Jameson's color-coded solutions as well as our expertise, and complementary training and asessments. At Nelson-Jameson, we also see the evolving threats to food safety — both new and old — and make it our mission to empower food processors to have the tools necessary to keep our food supply safe. Below we share more about why color-coding is so important for any food manufacturing facility’s regulatory compliance efforts. And learn more about color coding with our complete guide!

Featured Posts

April 14, 2025

Is Color-Coding Right for Your Food Processing Facility?

April 14, 2025

Color-Coding for Better Food Safety

May 6, 2025

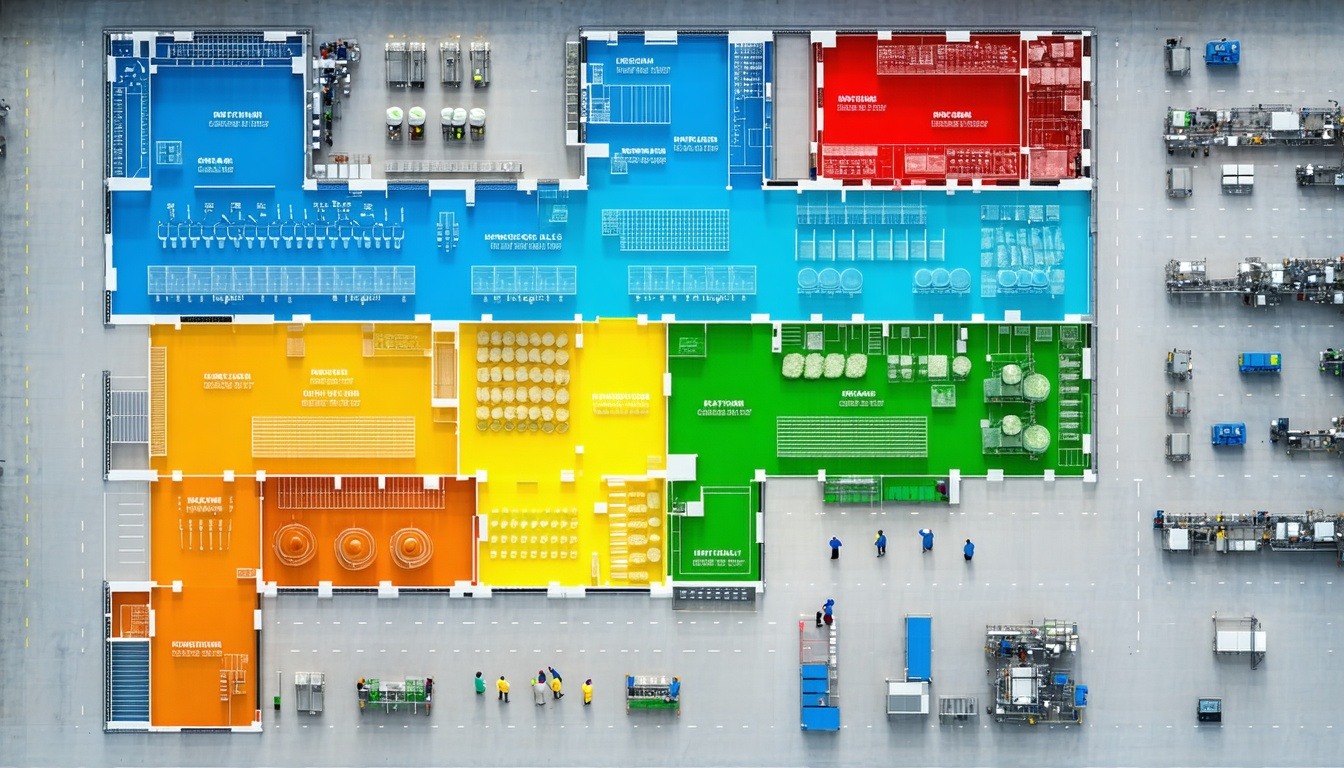

Enhanced Safety, Efficiency: Color Coding in Food Production Areas

In the fast-paced food processing production area, maintaining order, preventing cross-contamination, and ensuring efficient workflow are always top-of-mind. As Nelson-Jameson shares with customers every day, color coding offers a simple yet powerful solution to these challenges. It's a visual language that communicates critical information instantly, minimizing risks and optimizing operations. Let's quickly explores the diverse applications of color coding within food processing production areas. And for a deeper dive, visit our complete guide to color coding here!

July 15, 2025

Webinar Recap: Elevating Your Color-Coding Program

Food safety is a primary concern for any manufacturer, driven by existing and new threats that call for robust protective measures for consumers and the food processors themselves. A crucial tool in this ongoing effort is a well-implemented color-coding program, which, as a recent webinar that we hosted alongside Vikan highlighted, is not a "set it and forget it" solution. It's an ongoing, iterative initiative.

September 25, 2025

Introducing the NEW Vikan® Compact Lobby Dustpan

An innovative lobby dustpan that transforms commercial cleaning. This is not just a basic dustpan; it has been designed with efficiency, hygiene, and durability in mind. Whether you work in the food processing, healthcare, or janitorial industry, this compact and hygienic lobby dustpan by Vikan is engineered to meet your needs.

October 15, 2025

Sparta® Bronco™—An Essential Piece of Color-Coded Facilities

The Sparta Bronco Round Container is a testament to durability and smart design. It’s not just a basic container—it has been engineered with longevity, efficiency, and hygiene at its core. Whether you work in food manufacturing, dairy processing, or any other hygiene-sensitive industry, it’s built to meet the unique demands of any facility.

Schedule a complimentary assessment

On-site or virtual facility assessments for a tailor-made color-coded food safety program

Recognize and address possible hygiene and sanitation challenges based on the cleaning and material handling equipment available in your facility.

March 25, 2025

How to Monitor and Audit Your Color-Coding System

As a part of the Nelson-Jameson product team, I help our organization identify and provide the tools to serve every area of food processing plants.

February 21, 2025

Good Practice Examples of Color-Coding

February 21, 2025

Potential Pitfalls in Color-Coding

March 25, 2025

Color-Coding for Food Safety: A Crucial Part of Regulatory Compliance

April 8, 2025

Documentation and Record-Keeping for Your Color-Coding System

Additional color-code resources to elevate your food safety program

WEBINAR | VISUALIZING FOOD SAFETY

Communicate & Iterate: Why improving color-coding is an ongoing initiative

With existing and emerging threats, food safety has never been more important to food manufacturers in protecting their consumers and their organization. Utilizing the best existing color-coding tools is a must, but your program should be an ongoing initiative to meet current food safety needs and stay ahead of new challenges.

Get in touch with a color-code specialist

Do you prefer a printed catalog?

Request a free Color-Coded Products catalog and have your color-coded tools and info at your fingertips.

Get your color-coding questions answered:

Discover the color-coded tools that fit your food safety program by visiting our dedicated buying guide. Our comprehensive selection will help you implement an effective color-coding program for enhanced food safety in your facility.

Request an assessment of your facility for a comprehensive evaluation of areas in your plant that will benefit from having a color-coded system. Our food safety specialists are also available to answer your questions or concerns.

While regulations like FSMA typically do not mandate specific color assignments, the principle of preventing cross-contamination is a core requirement. Color-coding is a widely recognized best practice that helps facilities meet these regulatory demands and achieve certifications like HACCP or GFSI.

A wide range of items can be color-coded, including brushes, scoops, squeegees, buckets, cutting boards, knives, aprons, gloves, and even waste bins. The goal is to color-code any item that could potentially move between different zones and cause contamination.